WELCOME TO VEDANTA METACAST PVT. LTD.

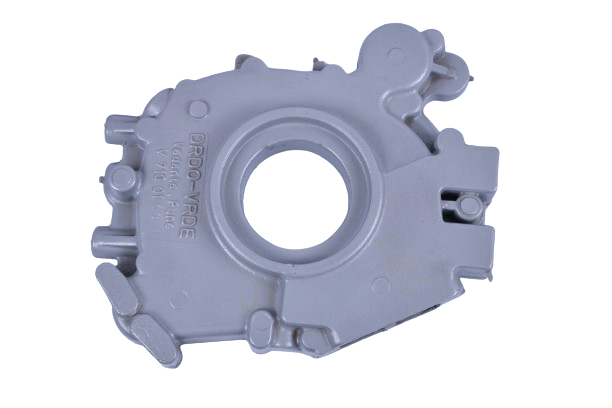

Vedanta Metacast Pvt Ltd is a leading IATF 16949:2016 & ISO 9001:2015 Certified “Aluminium Gravity Die Castings Company specialized in manufacturing of Die casting fully finished products.

Vedanta Metacast is expertise in reverse engineering/RPD/NPD for parts which are absolutely required & is mission-critical to a system.

We are committed to develop and expand the range of casting products for Autonmotive, Industrial, Electrical, Defence Industry, to maintain the pace of growth by adapting the latest technology and cost control systems, as per customer requirements.

OBJECTIVES

- To Create and Maintain a safe and healthy work environment for employees to perform their duty.

- To make the Factory Accident Free.

- To integrate Safety and health measures in all activities.

- To make the Factory and surroundings environment pollution free.

Our company is in the process of acquiring ISO 14001:2015 & ISO 45001:2018 certification.

Vedanta Metacast Pvt Ltd has 23 years experience in GDC Die/Tooling designing & manufacturing with a future plan to do Inhouse Tool Room.

- Till date we have made more than 40 No’s of Dies & supported our Customers for casting approval & its Mass Production.

- We Outsourced the Die / Tooling’s from our dedicated subcontracted Suppliers.

- Vedanta has In house conventional facility to do preventive die maintenance & minor modification in the Dies/ Tooling’s.

- In this intensely competitive global market, Vedanta is expertise in reverse engineering/NPD for parts which are absolutely required & is mission-critical to a system.

The approval of NPD Die/ Tooling’s as a process require various trials, but our expertise proves Dies/Tooling within T3 trials depending upon the Criticality of Components.

- Our products are made with the help of latest machinery in accordance with set industrial standards with our latest technological know-how & years of experience.

- We have Casting Simulation facility / Mold Flow analysis by using Simulation Software. We are also developing casting 3D model from 2D drawing & generating tool design as per tool Layout in CAD.

- Die Lead Time: As per casting criticality & design it takes 4 weeks to 16 weeks.

- Weight of Casting-0.500 kgs to 60 kgs castings die designed & Manufactured.

We have In-house facility,

- Faro Arm (USA) for checking the dimensions.

- Spectrometer of Bruker-GmbH make for Alloy chemical composition checking. It can check 14 elements.

- Only X-Ray/Radiography testing is outsourced to check porosity.

- CRISIL Rating for Financial Credentials & DUNS Number.

- We have team of 200 + employees (constantly rising).

About Vedanta

Vedanta Metacast Pvt. Ltd. started production of Gravity Die Castings at pune since 2011. Within a short span we have established ourselves as pioneer in developing critical Casting components….

Process

Best Quality Products

Vedanta is known for its Highly Durable and Quality Products in Automotive, Industrial/Electrical and Defense Industry.

OUR VALUEABLE CUSTOMERS