Skip to content

Die Making

- Vedanta Metacast Pvt Ltd has 23 years experience in GDC Die/Tooling designing & manufacturing with a future plan to do In-house Tool Room.

- Till date we have made more than 40 No’s of Dies & supported our Customers for casting approval & its Mass Production.

- We Outsourced the Die / Toolings from our dedicated subcontracted Suppliers.

- Vedanta has In house conventional facility to do preventive die maintenance & minor modification in the Dies/ Tooling’s.

- In this intensely competitive global market, Vedanta is expertise in reverse engineering/RPD/NPD for parts which are absolutely required & is mission-critical to a system.

- The approval of NPD Die/ Tooling’s as a process require various trials, but our expertise proves Dies/Tooling within T3 trials depending upon the Criticality of Components.

- Our products are made with the help of latest machinery in accordance with set industrial standards with our latest technological know-how & years of experience.

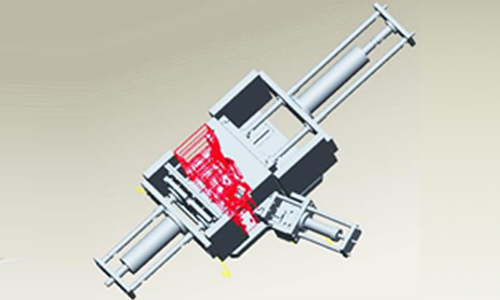

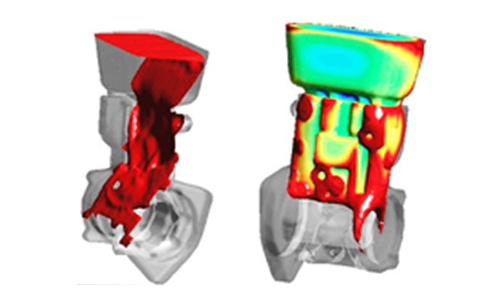

- We have Casting Simulation facility / Mold Flow analysis by using Simulation Software-“Click to Cast”

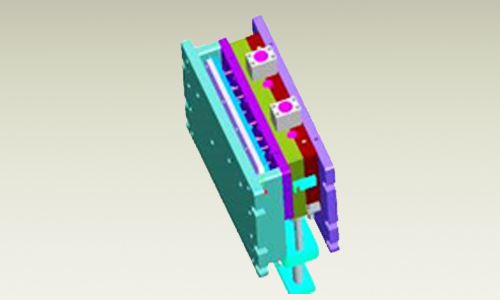

- We are also developing casting 3D model from 2D drawing & generating tool design as per tool Layout in CAD.

- Die Lead Time : As per casting criticality & design it takes 4 weeks to 16 weeks.

- Weight of Casting- 0.500 kgs to 60 kgs castings die designed & Manufactured.

- Team Size- 15 Nos